Why Every DIYer Needs a Quality Foam Gun

For DIY enthusiasts and professionals alike, having the right tools can make all the difference in project outcomes. A quality foam gun is one such tool that often goes overlooked but offers unmatched precision, efficiency, and versatility. Whether you're working on insulation, sealing gaps, or crafting, a foam gun ensures smooth, controlled application of foam or adhesive, reducing waste and improving results. This article explores the benefits, applications, and key features of foam guns, along with comparisons to other tools like glue guns, saw blades, and drill bits.

What Is a Foam Gun?

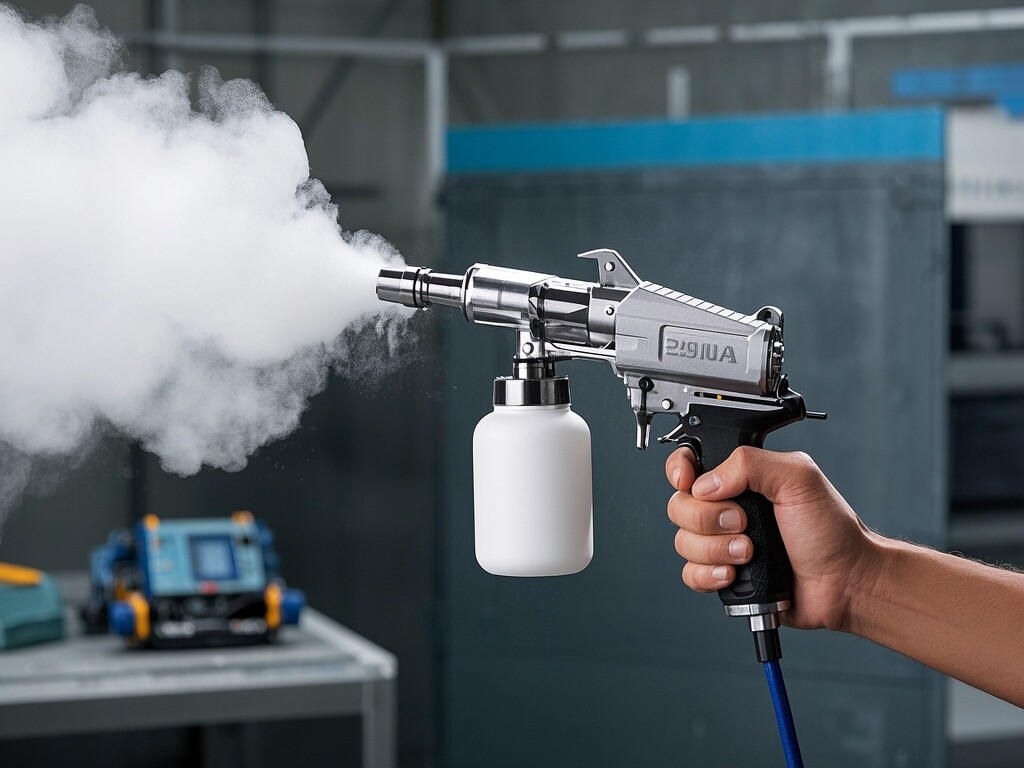

A foam gun is a specialized tool designed to dispense foam or adhesive materials with precision. Unlike traditional methods like using a straw or manual applicator, a foam gun allows for controlled flow and even distribution, making it ideal for tasks requiring accuracy. Foam guns are commonly used in construction, insulation, and crafting projects, where consistency and efficiency are paramount.

Key Benefits of Using a Foam Gun

- Precision Application: Foam guns enable pinpoint accuracy, reducing overspray and waste.

- Efficiency: They allow for faster completion of tasks compared to manual methods.

- Cost Savings: By minimizing waste, foam guns help save on material costs.

- Versatility: Suitable for various materials, including polyurethane foam, adhesives, and sealants.

Applications of Foam Guns

Foam guns are indispensable in numerous scenarios, including:

- Insulation: Perfect for filling gaps and cracks in walls, roofs, and floors.

- Sealing: Ideal for weatherproofing windows and doors.

- Crafting: Useful for DIY projects requiring precise adhesive application.

- Automotive: Helps in soundproofing and vibration damping.

Foam Gun vs. Glue Gun: Which One to Choose?

While both tools dispense adhesives, they serve different purposes. A foam gun is designed for larger-scale projects like insulation, whereas a glue gun is better suited for small-scale crafting. Foam guns offer better control over flow and are more durable for heavy-duty tasks.

Technical Specifications to Consider

How to Choose the Right Foam Gun

When selecting a foam gun, consider the following factors:

- Material Type: Ensure the gun is compatible with the foam or adhesive you plan to use.

- Flow Control: Look for adjustable flow settings for better precision.

- Build Quality: Opt for durable materials like stainless steel for longevity.

- Ease of Cleaning: Choose a model that is easy to disassemble and clean.

Common Misconceptions About Foam Guns

Many DIYers believe foam guns are only for professionals or large projects. However, even small tasks can benefit from the precision and efficiency of a foam gun. Another myth is that foam guns are difficult to clean, but modern designs are user-friendly and easy to maintain.

Industry Standards and Certifications

Reputable foam guns often meet industry standards like ISO 9001 for quality management. Look for certifications to ensure you're investing in a reliable tool.

Cost Analysis: Foam Gun vs. Traditional Methods

While foam guns may have a higher upfront cost, they save money in the long run by reducing material waste and improving efficiency. Traditional methods like manual applicators often lead to uneven application and higher material consumption.

Customer Case Studies

John, a DIY enthusiast, shared how switching to a foam gun reduced his insulation project time by 50% and saved him 30% on material costs. Similarly, a small contractor reported higher customer satisfaction due to the professional finish achieved with a foam gun.

FAQ About Foam Guns

- Q: Can I use a foam gun for small projects?

A: Absolutely! Foam guns are versatile and suitable for projects of all sizes.

- Q: How do I clean a foam gun?

A: Most foam guns can be cleaned with acetone or a specialized cleaner. Always follow the manufacturer's instructions.

Future Trends in Foam Gun Technology

The foam gun market is evolving with innovations like battery-powered models and smart flow control systems. These advancements promise even greater precision and convenience for users.

Why Choose a Quality Foam Gun?

Investing in a quality foam gun ensures better project outcomes, cost savings, and professional results. Whether you're a DIYer or a professional, a foam gun is a must-have tool in your arsenal.

Ready to upgrade your toolkit? Explore our range of high-quality foam guns and experience the difference today!

Related Posts

- ▶ Dripless Dual-Cartridge Caulking Gun: Innovation for Multi-Material Applications

- ▶ Caulking Gun Size Guide: Matching Chaohui Tools to Your Project Needs

- ▶ Eco-Friendly Foam Gun: Durability Meets Sustainability for Long-Term Use

- ▶ Foam Gun: Precision Control & Waste Reduction for Professional Sealing

- ▶ Best Foam Gun for Professionals: Top 5 Picks in 2024

- ▶ How to Choose the Right Saw Blade for Your Project?

Send Us A Message